What an air handling unit is?

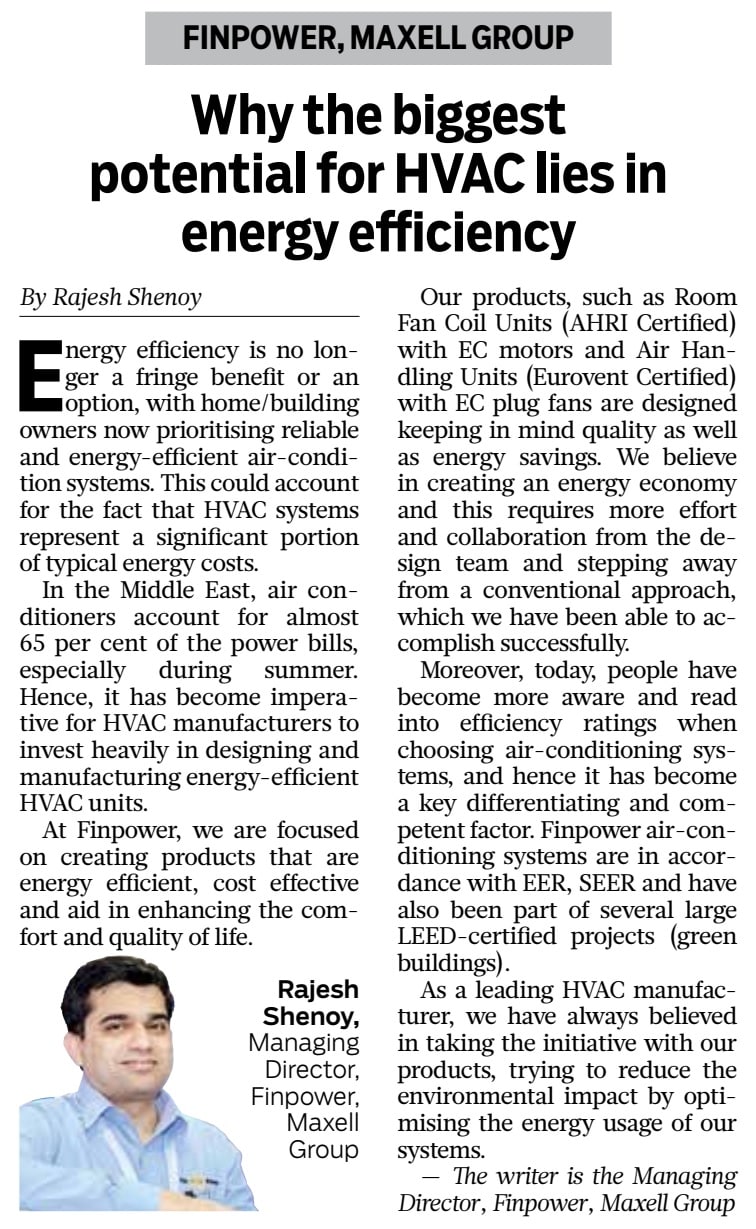

Air handling unit commonly named as AHU or air handler is a marvelous equipment that handles air the way a building needs. Commonly made with light weight profiles for sturdy structure. They comprises of filter section, coil section and fan motor section.

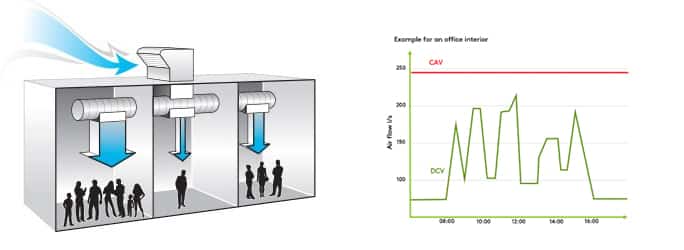

They collects the air from outside ambient or from room, clean the air though filtration process, cool the air through coil cooling process and supply the temperature and humidity controlled air in to the room for comfort.

Fan motor section at the end of the unit is drawing this air through the duct. This is then supplying the controlled air in to the rooms or the area where it is to be served.

These units are normally placed inside a mechanical room or on the roof .Placement is often based on the space availability as these are comparatively larger units when compared to small standard room cooling units. These units are customized and tailor made as per the building requirements. These are provided with special accessories based on custom design like heaters, UV lamps, humidifier, heat pipes etc.

Working mechanism of air handling unit

A simple mechanism in which a filter section, coil section and fan motor section is there. Air is drawn through filter, cooling coil and then supplied through the duct to serving area. Filter section cleans the impurities in air, cooling coil which is mechanically bonded copper tube and aluminum fins cools the air, sometime provided with heater for reheating based on the temperature needed.

Do we need an air handler !!

Indoor air quality is must these days for human to live a comfortable life. Compared to other smaller units, this units gives us the flexibility of choosing wide range of airflow and capacity to cool or heat for any sized commercial residential building. This can be made as a combination to work with chilled water cooling or refrigerant based cooling mechanism.

As it’s always placed in mechanical room or roof tops, easy to access and clean to upkeep the maintenance. Reduced cost when compared to placing multiple small units to cool a particular area. Maintenance on multiple units is more when compared to maintenance on one large indoor unit

Careful selection of air handling unit

If the unit is not well designed understanding the load and application that could be a waste of money and energy. It is also recommended to have multiple unit so that in case one unit is failed, end user expecting the comfort should not be effected.

Application of air handling units

AHU’s are commonly used in commercial and industrial buildings, such as office buildings, hospitals, schools, Shopping malls, and manufacturing facilities. They play a critical role in maintaining indoor air quality and ensuring the comfort and health of building occupants

Main use of air handling units !!

The main use of an air handling unit (AHU) is to regulate and circulate air within a building to maintain a comfortable and healthy indoor environment. They are commonly used in commercial and industrial buildings, such as office buildings, hospitals, schools, and manufacturing facilities. They serve several important functions, including:

Heating and cooling: Air handler can include heating and cooling elements that help to regulate the temperature of the air being circulated throughout the building.

Humidity control: They can also include humidifiers and dehumidifiers that help to regulate the humidity levels in the building.

Air filtration: They typically include filters that remove dust, pollen, and other airborne contaminants from the air being circulated, improving indoor air quality.

Ventilation: They can also include provisions for bringing in fresh outdoor air to replace stale indoor air, improving overall air quality and promoting occupant health.

Overall, the use of an Air handling unit is critical for maintaining a comfortable and healthy indoor environment, improving indoor air quality, and ensuring the safety and well-being of building occupants.

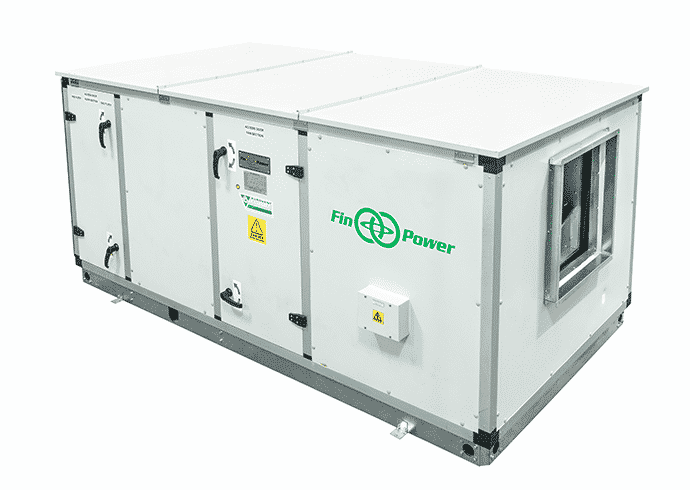

Air handling units use a chiller or Condensing unit or VRF as heat source equipment and exchange heat between chilled/heated water or refrigerant and air to adjust the air temperature. Therefore, air handling units offer excellent operational flexibility. For example, medium-/large-size buildings can be installed with a combination of chillers and AHU’s, while small-/medium-size buildings can use a combination of VRF‘s and AHU’s.

Differences between air handling unit and fan coil unit

In a sense, air handling units are installed for the purpose of cooling/heating the entire building, but fan coils are used for cooling/heating individual rooms. Fan coil units also require a heat source medium.

Generally, heated/chilled water serves as a heat medium for fan coil units (FCU). Water heated or chilled from another location is sent to the fan coil unit for use in providing warm/cool air to the rooms.

Fan coil unit also come with accessories as option based on the design. Some fan coil units are provided with heater banks before or after the cooling coil based on the purpose of sensible heating or de humidification purpose.

Some designs demands for UV in front of the coil at discharge side to eliminate pathogens especially where the air is been served to sensitive areas like laboratory, hospitals rooms etc.

Differences between air handling unit and Fresh air handling unit

A Fresh Air Handling Unit (FAHU) is a type of AHU that is specifically designed to bring in and condition fresh outside air. It is typically used in buildings where there is a high demand for fresh air, such as hospitals, laboratories, or other commercial / residential buildings where indoor air quality is of utmost importance.

Unlike a regular AHU, a FAHU does not recirculate air within the building. Instead, it pulls in fresh outside air, filters it, and then conditions it before distributing it to various parts of the building. There are several options of energy saving with heat recovery wheel and de humidification and RH factor maintenance by heat pipe.

In summary, the main difference between an AHU and a FAHU is the source of the air they handle. While an AHU can handle both fresh outside air and recirculated air from within the building, a FAHU is specifically designed to handle only fresh outside air.

How Does Your Air Conditioning and Indoor Air Quality Connect?

How Does Your Air Conditioning and Indoor Air Quality Connect?